In another popular forums called motor bicycling apparently its an old joke, "look at how I mounted my china girl". If you do a lousy job of it your buddy's all get to laugh at you. Well, I am no exception to the rule myself. I used all of my mechanical ability and years of experience in engineering custom fabricated projects, and came up with what appeared to be a fool proof concept and as it turns out I was the fool.

I developed a motor mount for my Schwinn Jaguar bicycle that....

Let me start with a little history, This kit (nick named the china girl because it is a cheap kit that is made in china) is designed to fit on one particular bicycle, and nobody really knows just what bike that is, all bikes have a similar design and this motor kit will "work" on all of them but just not easily. Some bikes have large frame tubes, some use a different span between the tubes, basically there is nothing universal about it.

So after determining that my choice of bicycle requires some modifications to the motor mounts to work on it, I created the following design.

This design completely prevents the engine from moving due to the centrifugal force generated by the crankshaft, however it's fatal flaw is that fails to prevent the engine from twisting due to the torque created by the chain and sprockets.

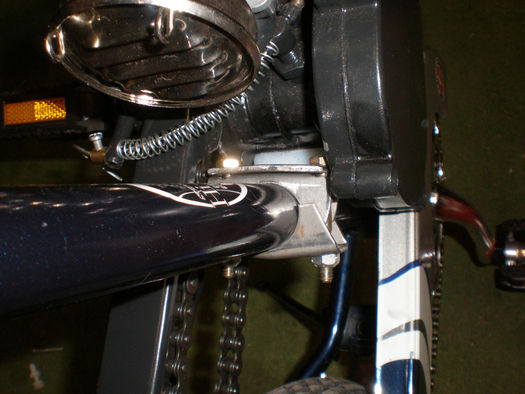

This is what happened to the rear mount after the front mount allowed the motor to twist.

This is a $5 part that I was able to order easily enough, but I had a revaluation that resulted in the following creation that has to this point held up much better, I have approximately one mile or so now of engine break in run time, and so far so good. I eliminated the stock pot metal spacer thingy and used 2 small muffler clamps as you can see. I also fabricated a small piece of very hard plastic to use as a spacer about 3/8 inches thick between the motor and the plate of metal. I hope this will help reduce vibrations and noise. In addition I added the muffler clamp saddle that I left out in the first attempt not realizing it played a vital role.

After riding the monster some tonight, I see a need the thought of vibration dampening to be elaborated on a touch in any future redesign of the mounts.

All in all this project has been great fun, and rewarding to get to this stage in the game.

Here is a photo of the bike as it sits now, I shortened the handle bars about 2 inches and moved the seat back as far as I could with a laid back seat post, it works like it is, but I may need to try some different style handle bars, or get a smaller belly that the bars wont hit when I turn the bike.

myke

I developed a motor mount for my Schwinn Jaguar bicycle that....

Let me start with a little history, This kit (nick named the china girl because it is a cheap kit that is made in china) is designed to fit on one particular bicycle, and nobody really knows just what bike that is, all bikes have a similar design and this motor kit will "work" on all of them but just not easily. Some bikes have large frame tubes, some use a different span between the tubes, basically there is nothing universal about it.

So after determining that my choice of bicycle requires some modifications to the motor mounts to work on it, I created the following design.

This design completely prevents the engine from moving due to the centrifugal force generated by the crankshaft, however it's fatal flaw is that fails to prevent the engine from twisting due to the torque created by the chain and sprockets.

This is what happened to the rear mount after the front mount allowed the motor to twist.

This is a $5 part that I was able to order easily enough, but I had a revaluation that resulted in the following creation that has to this point held up much better, I have approximately one mile or so now of engine break in run time, and so far so good. I eliminated the stock pot metal spacer thingy and used 2 small muffler clamps as you can see. I also fabricated a small piece of very hard plastic to use as a spacer about 3/8 inches thick between the motor and the plate of metal. I hope this will help reduce vibrations and noise. In addition I added the muffler clamp saddle that I left out in the first attempt not realizing it played a vital role.

After riding the monster some tonight, I see a need the thought of vibration dampening to be elaborated on a touch in any future redesign of the mounts.

All in all this project has been great fun, and rewarding to get to this stage in the game.

Here is a photo of the bike as it sits now, I shortened the handle bars about 2 inches and moved the seat back as far as I could with a laid back seat post, it works like it is, but I may need to try some different style handle bars, or get a smaller belly that the bars wont hit when I turn the bike.

myke